Medical PCB is widely used for kinds of medical devices such as diagnostic devices, monitoring devices, healthcare devices, and treatment devices. In fact, almost every medical electronics require to use of printed circuit boards. In this article, we will focus on key standards and regulations of medical PCB design.

The medical device can be divided into three classifications:

Class I: A medical device with low to moderate risk

These products are generally low risk. Although they are used in some medical procedures, they are not easy to cause personal injuries, such as electronic scales, gauges, and dental mirrors.

Class II: A medical device with a moderate to high risk

These products have higher risks than Class I products but are limited to operational and maintenance risks, such as electric wheelchairs and monitoring instruments.

Class III: A medical device with the highest possible risk

These products are essential and must be manufactured to the highest standards to ensure their high reliability. We know that medical devices must meet specific standards while meeting some special criteria, whether in terms of functionality, production, or quality systems.

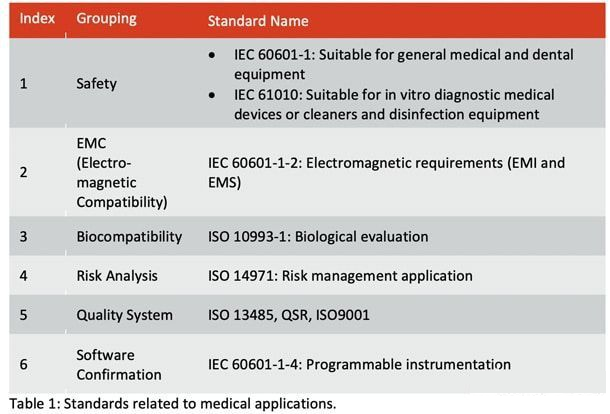

Table 1 Lists some key criteria related to medical devices:

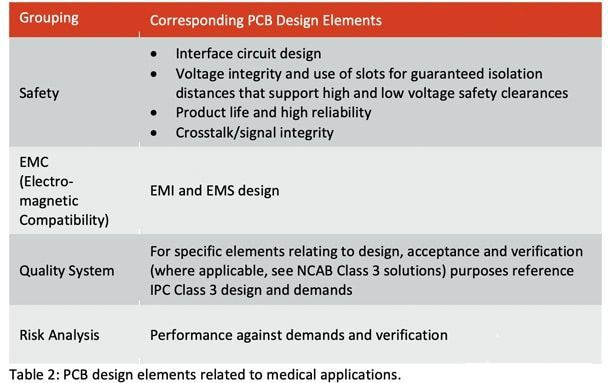

Meanwhile, it is important to consider how these standards are corresponding to PCB design elements (refer to Table 2).

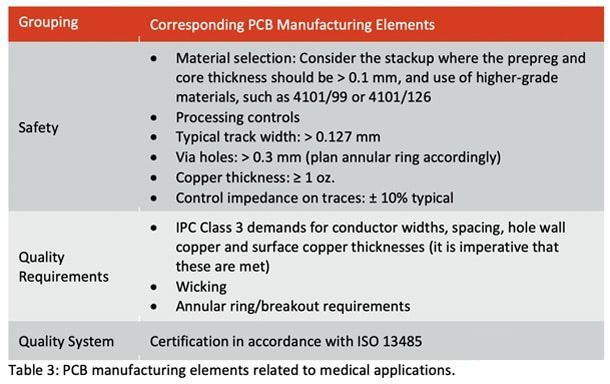

After evaluating design elements, manufacturing elements corresponding to medical applications must also be considered. These elements may directly affect the quality and reliability of the PCB. The elements in Table 3 are critical when it comes to security.

In addition to the above elements, there are many strict standards to be followed.

For example, the cleaning requirements exceed IPC standards, and some manufacturers are even required to use renowned substrate types. The solder mask on the PCB surface and the conductor surface need to be reached a specific thickness. When a Type VI solder mask is required, the requirements for vias plug depth are more strict.

PCB designs for medical applications require specific components to meet power, signal quality, crosstalk, and grounding requirements, but the most important are reliability and safety.

Safety is the key issue, including radiation, electrical performance, thermal performance, and mechanical safety, all driven by IPC Level 3 standards. Therefore, it is critical to have a reliable manufacturer that can meet these requirements and provide reliable circuit boards for medical applications.

whatsapp

whatsapp