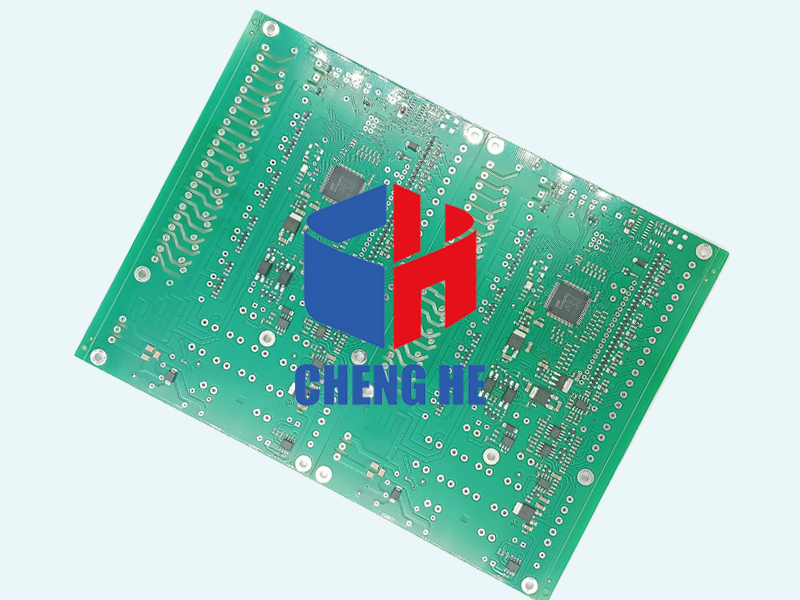

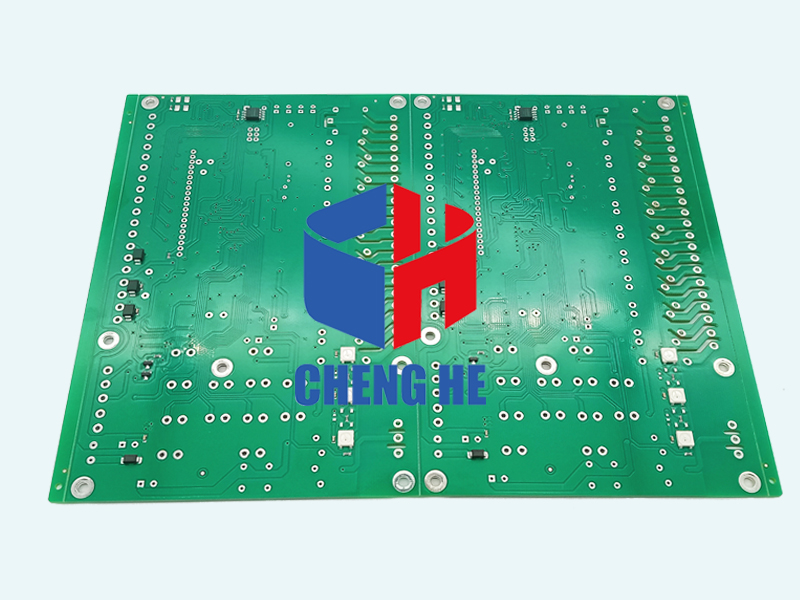

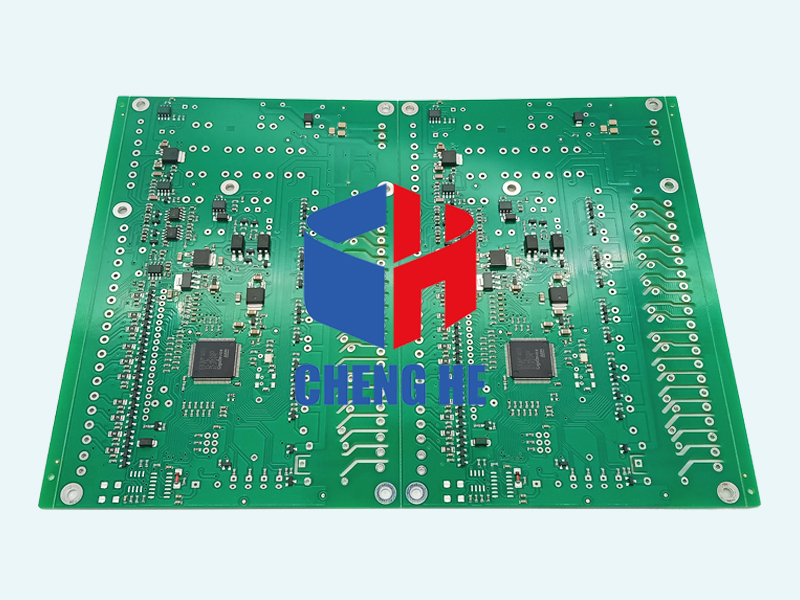

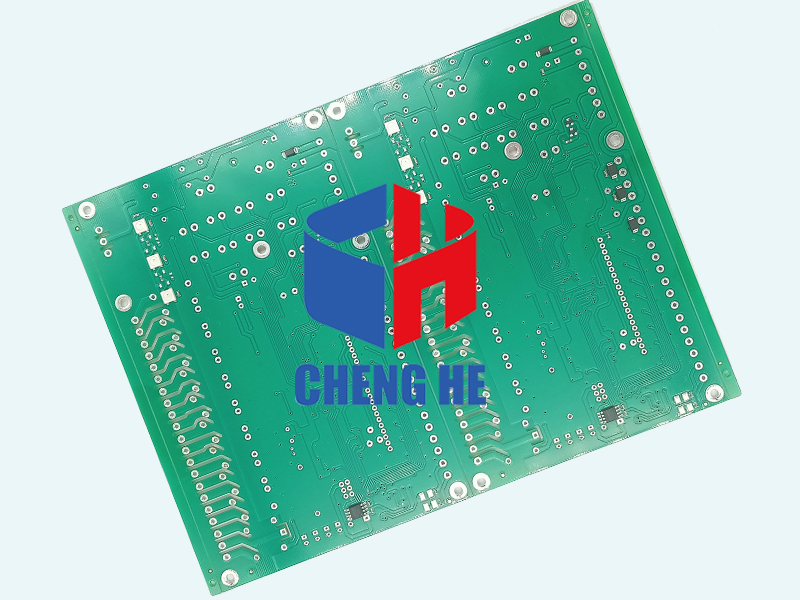

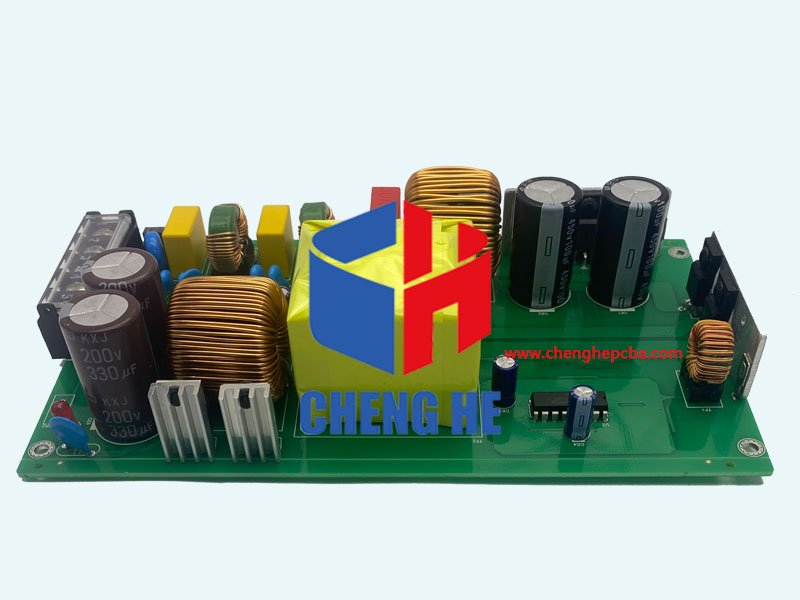

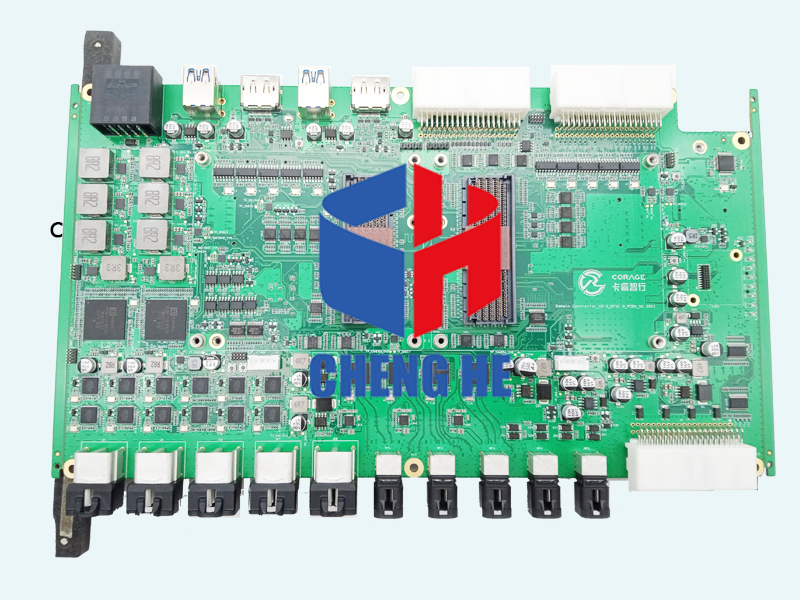

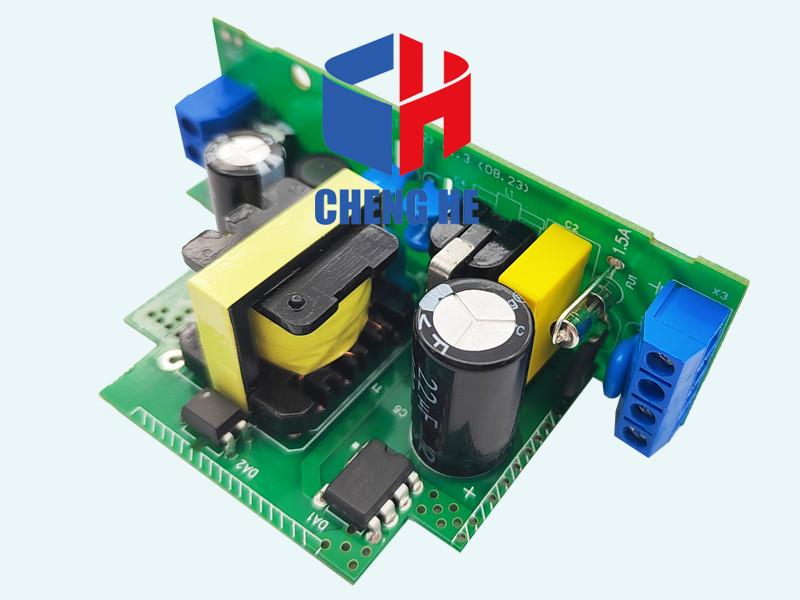

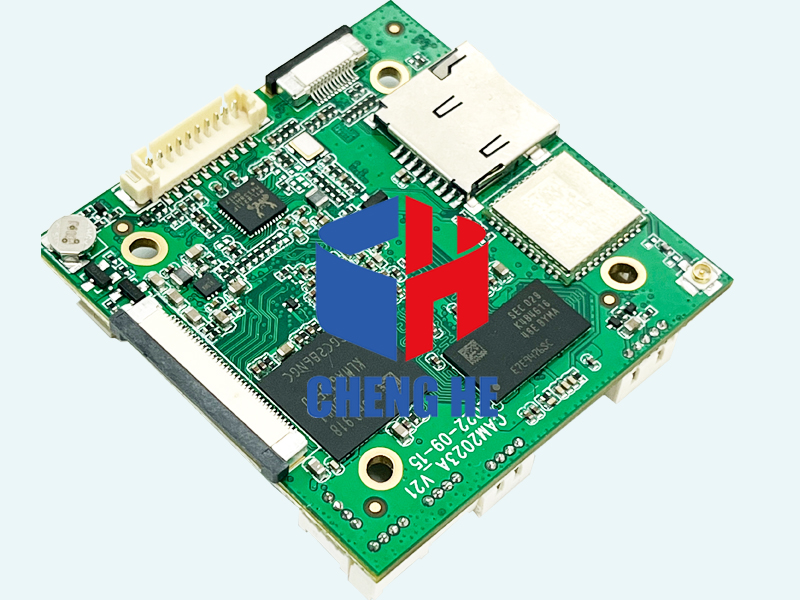

Material: | FR4 | Layer: | 2L |

Board thickness: | 1.6mm | Min Hole: | 0.3MM |

Copper thickness: | 1 OZ | Solder mask: | Green |

Min Width & Space: | 0.3/0.3mm | Silkscreen: | None |

Finishing: | LF HASL | Application: | Industrial Controller board |

Special: | |||

What is Design for Manufacturability?

Considering the manufacturability of the product from the beginning of design, improve the First Pass Yield and reliability of the product, make the product easier to manufacture and reduce the manufacturing cost.

During the design stage of the product, the process requirements, test requirements and the rationality of assembly in the manufacturing process are considered comprehensively, and the cost, performance, quality of the product are controlled by means of design.

Generally speaking, the design of manufacturability mainly includes three aspects: PCB manufacturability design, PCBA assembly design, and low manufacturing cost design.

PCB Manufacturability Design

Considering the manufacturing process parameters, so as to improve the First Pass Yield of board manufacturing and reduce the process communication cost. For example, whether the line width and distance are designed enough, whether the design can meet the real production requirements of the factory.

PCB Assembly Design

Considering how to standardize the layout, how to design the PCB package correctly, the heat dissipation balance etc. The standard layout generally considers that the distance between devices should not be too close, and spatial interference cannot occur. PCB packaging is mainly based on the consideration of welding performance, components and PCB solder pads need to be matched

Low Manufacturing Cost Design

The market competitiveness of a product depends largely on its cost. When choosing the manufacturing process, the designer should choose better and simple one as much as possible in the premise of quality assured.

whatsapp

whatsapp