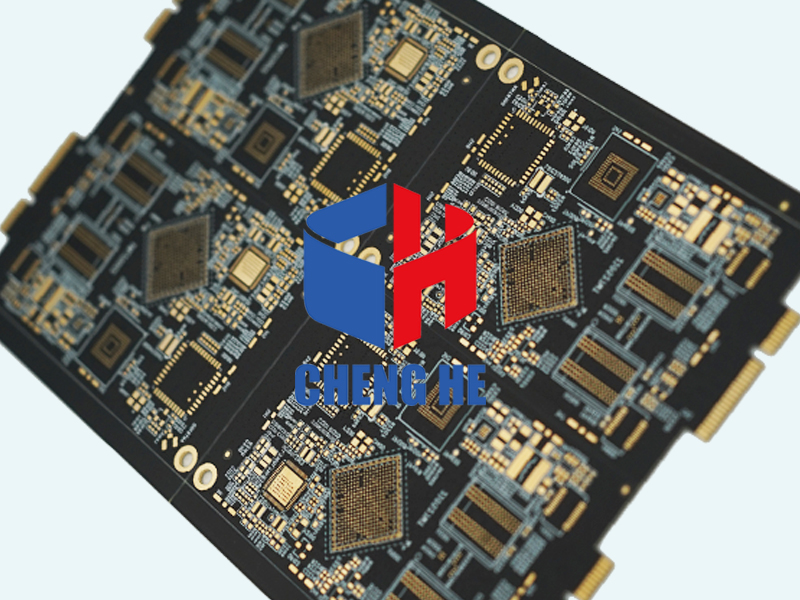

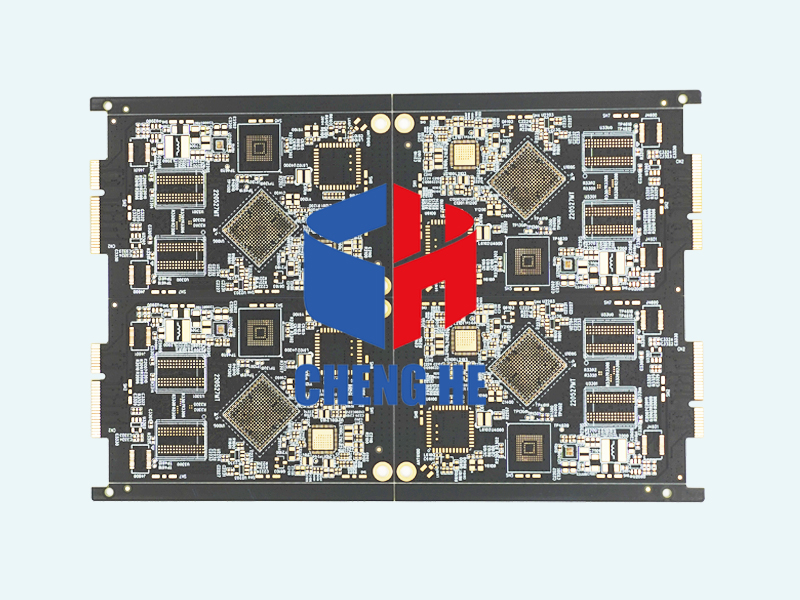

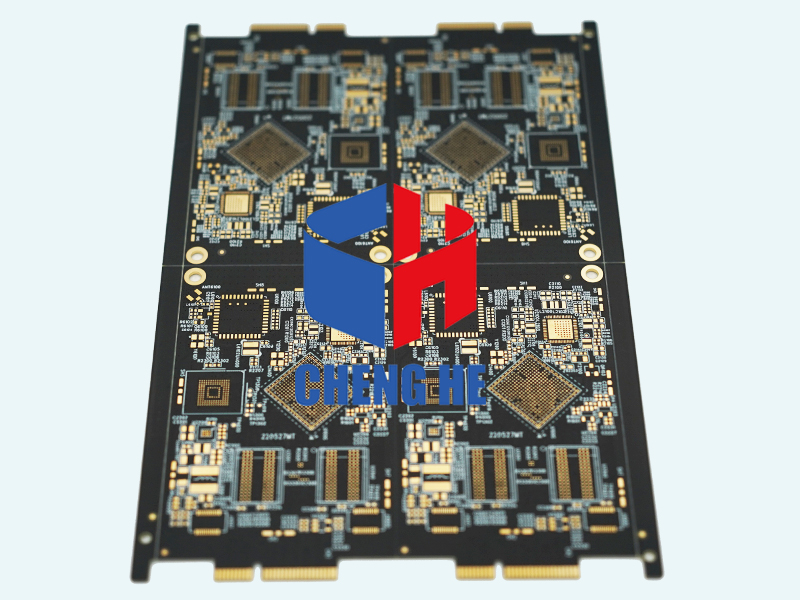

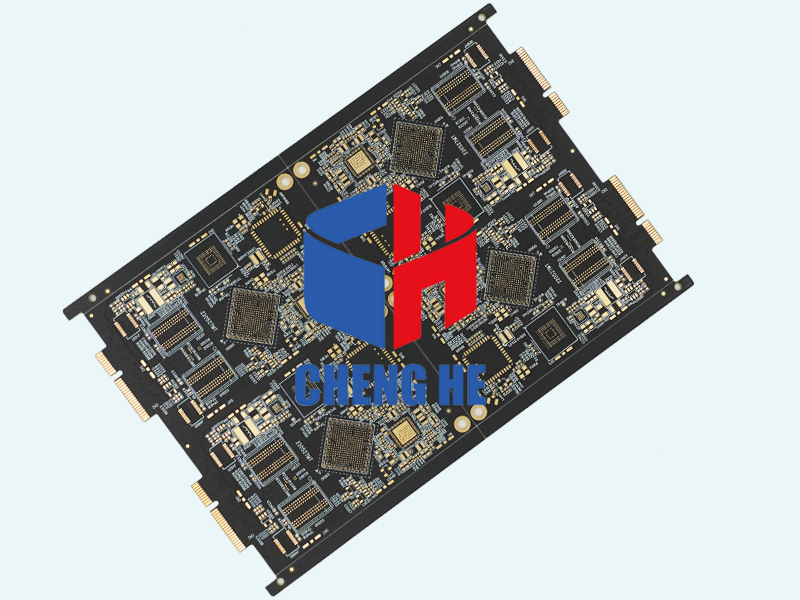

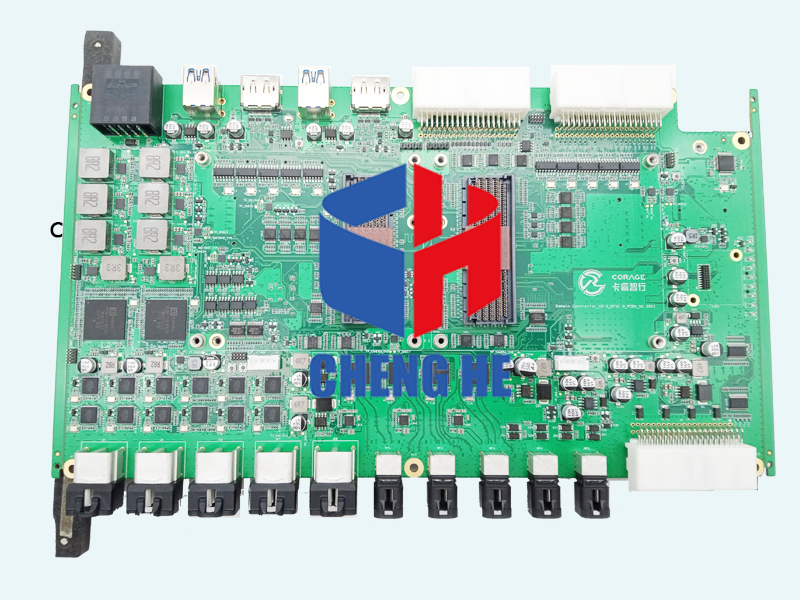

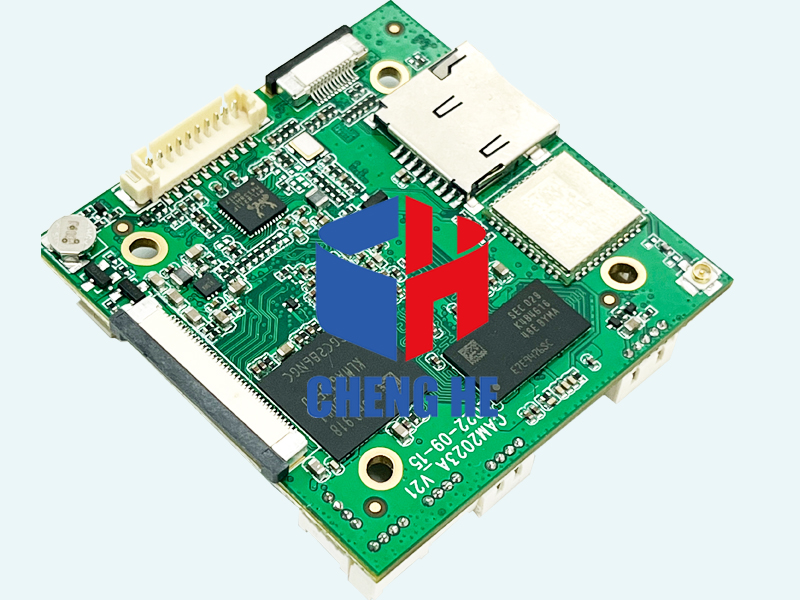

Material: | FR4 | Layer: | 6L |

Board thickness: | 1.6mm | Min Hole: | 0.2MM |

Copper thickness: | 1OZ | Solder mask: | Black |

Min Width & Space: | 5mil/5mil | Silkscreen: | White |

Finishing: | Immersion gold | Application: | Core main PCB for RK3566 |

Special: | Core board for core moudle of RK3566 | ||

Emergency Procedures for PCB Short Circuit

PCB short is one of the most common issues leading PCB boards to fail, and there are many causes. The causes will be discussed in the order of significance, and emergency solutions will be given.

• Emergency measure#1. The foremost cause for short on PCB lies in the improper design of the pad. To stop the place from causing PCB fast, the shape of a residence can be designed to be oval instead of a circle so that the distance between points can be enlarged and short can be avoided.

• Emergency measure#2. The incorrect placement direction of components can also make PCB suffer from short. Under such conditions, component placement direction should be adjusted correctly to stop short from taking place.

• Emergency measure#3. Another cause for PCB short is bent pins on SMT (Surface Mount Technology) components. To effectively solve this issue, the solder joint should be 2mm away from the circuitry.

• Other causes. Apart from the leading causes of PCB short mentioned above, some reasons can never be neglected, including too large substrate hole, low soldering temperature, bad solderability of the board, unworkable solder mask, board surface pollution etc.

whatsapp

whatsapp