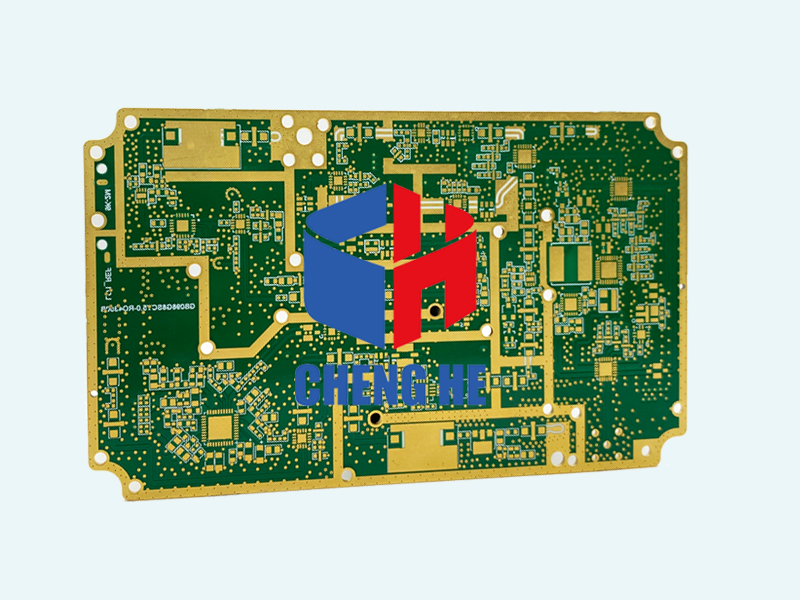

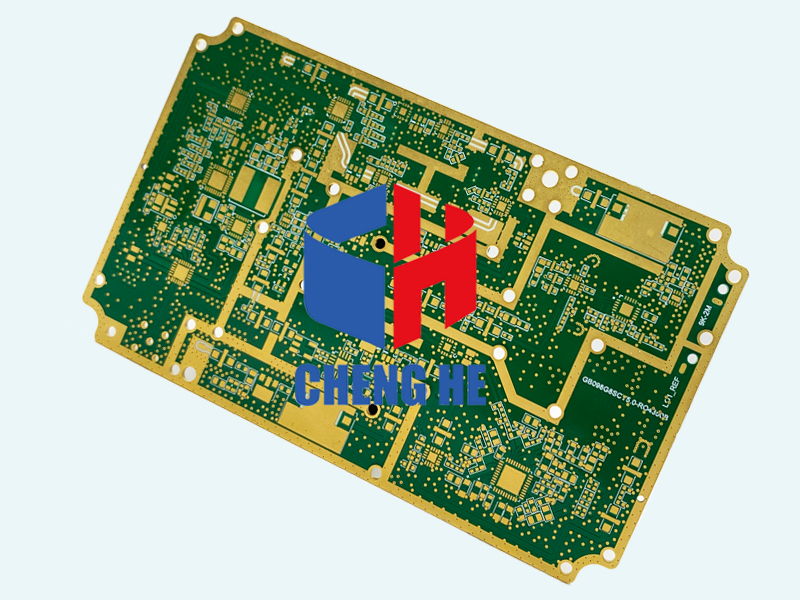

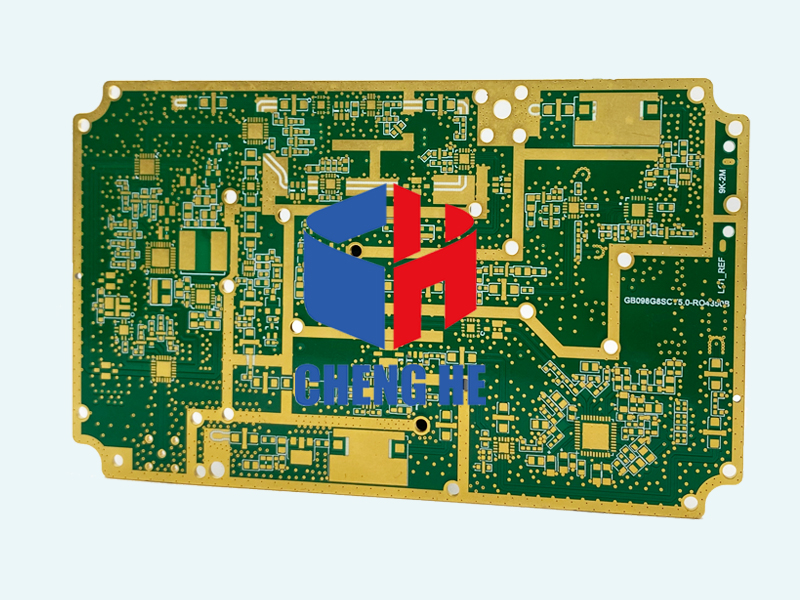

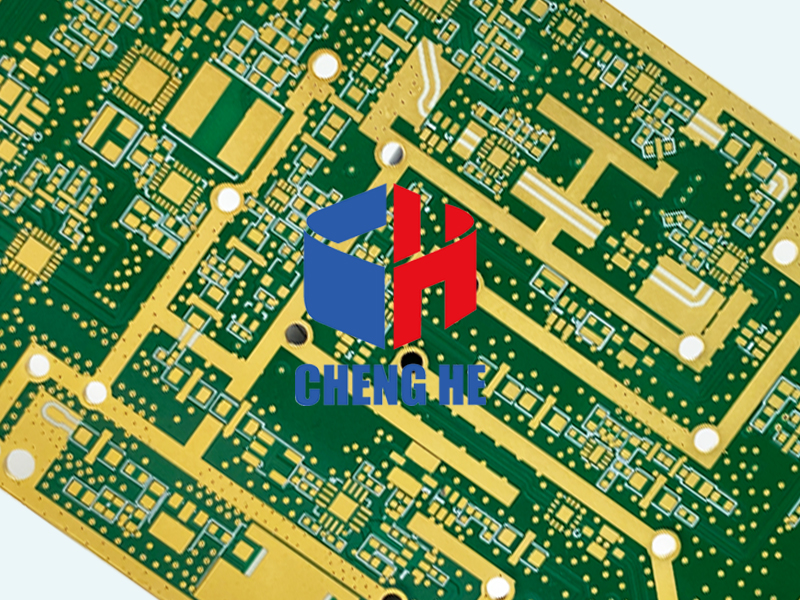

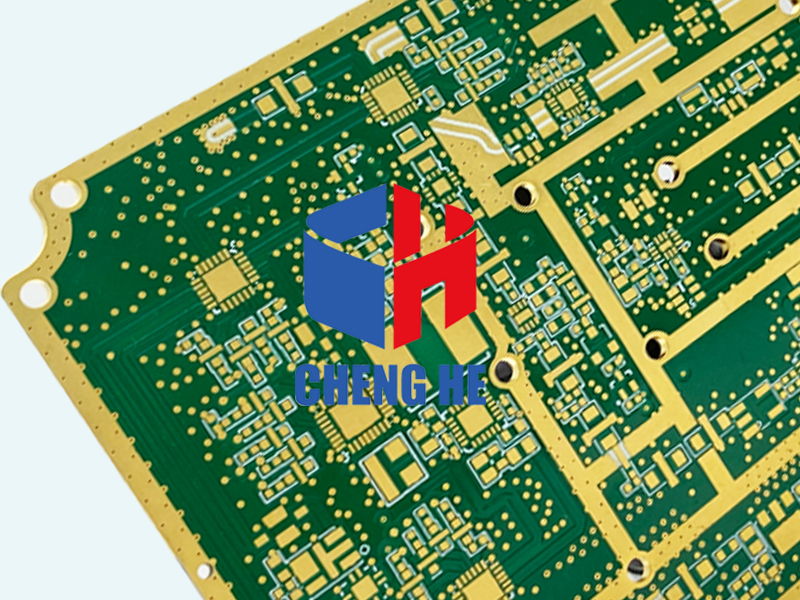

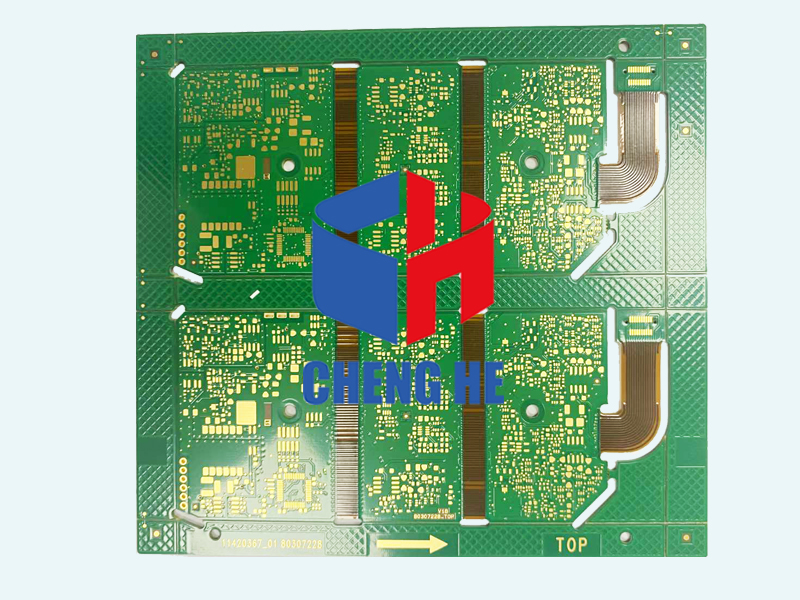

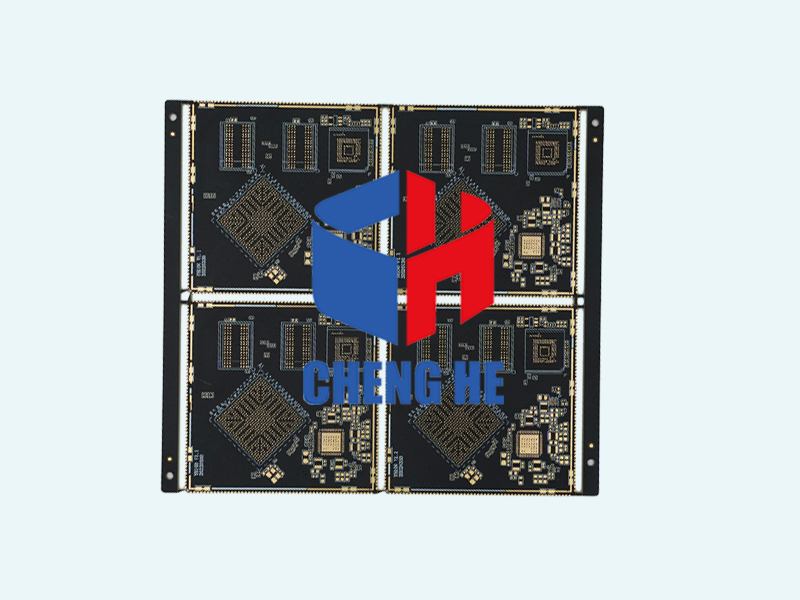

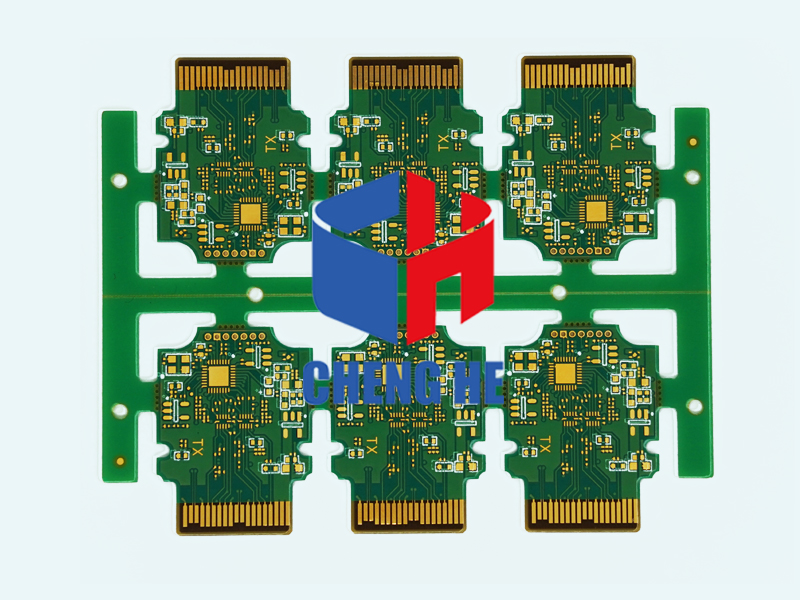

Material: | FR4,M7 | Layer: | 6L |

Board thickness: | 1.6mm | Min Hole: | 0.2mm |

Copper thickness: | 1 OZ | Solder mask: | Green |

Min Width & Space: | 0.25mm/0.25mm | Silkscreen: | White |

Finishing: | Immersion Gold 2u" | Application: | Bluetooth Speaker |

Special: | Big ENIG Area | ||

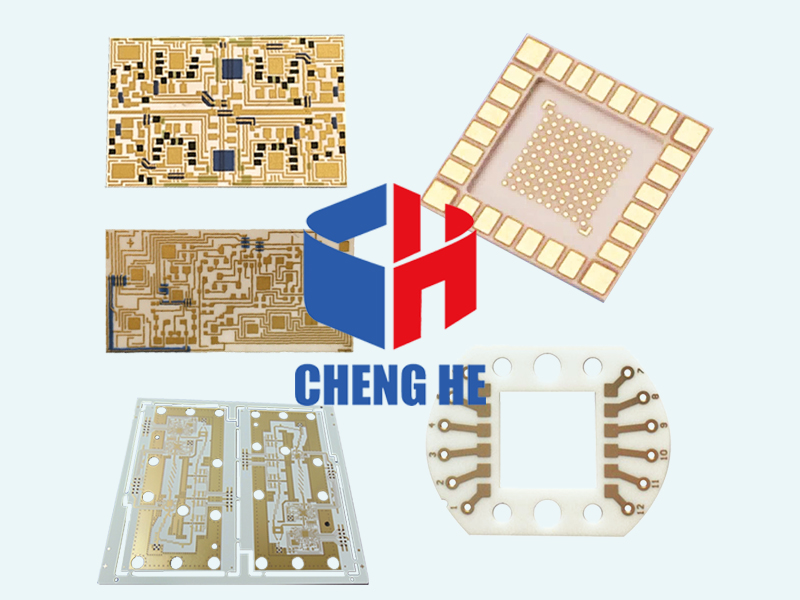

What is immersion gold PCB?

"Immersion Gold" means "nickel immersion gold", which is one of the surface finish for PCB.

Immersion gold is cheaper than gold plated, so the shiny part of electronic parts is usually immersion gold.

A thin layer of gold prevents oxidation of copper.

The difference between immersion gold and gold plating

Gold is using for surface finish of PCB, such as key board and gold finger and so on, as the gold has a great conduction, strong oxidation resistance, long life. However, it is essential difference between plating gold and plating gold that plating gold is hard gold as well to resistance, but immersion gold is flexible gold which is on the contrary.

There are some differences between immersion gold and gold plating as follows:

1. Gold thickness in immersion gold board is more than that in a gold plating board. Immersion gold board is more yellow than a gold-plating board, that’ because gold-plating board has the color of nickel.

2. Their crystal structures are different. Comparatively speaking, immersion gold is easier to be soldered with less poor solder issues. Immersion gold board is easier to control the stress, which is benefit for the bonding products. At the same time, immersion gold has a poor anti - abrasion when doing gold finger as immersion gold is more flexible than plating gold.

3. Nickel is only used on immersion gold board’s pad, thus the signal transmission in the skin effect does not affect the signal at the copper layer.

4. The crystal structure of immersion gold is much denser than that in gold plating board, thus it is not easy to produce oxidation.

5. With the strict requirements for higher precision in PCB fabrication process, line width and spacing have below 0.1mm. Gold-plating board is easier to produce short circuit than immersion gold board.

6. Nickel is only used on immersion gold board’s pad, therefore solder resist on the circuit is solidly combined with the copper layer.

7.The flatness and service life of immersion gold board is better than the gold plating board.

whatsapp

whatsapp