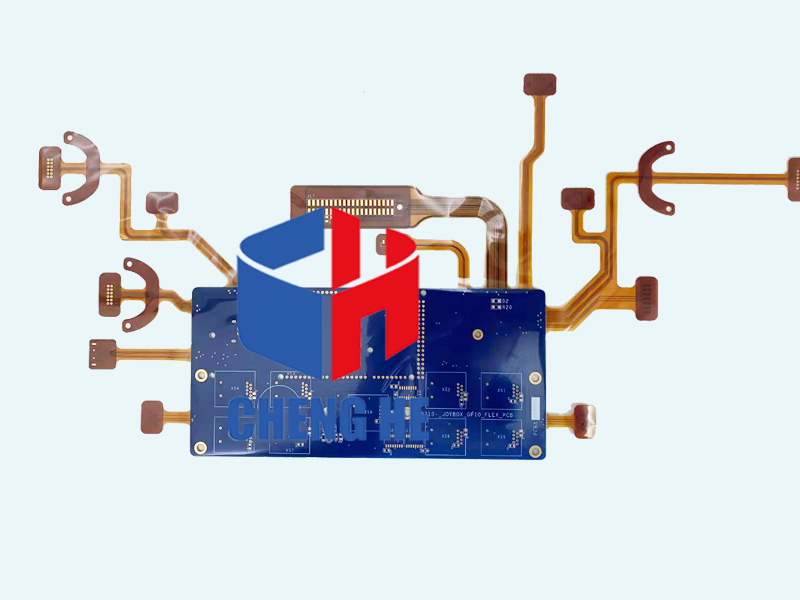

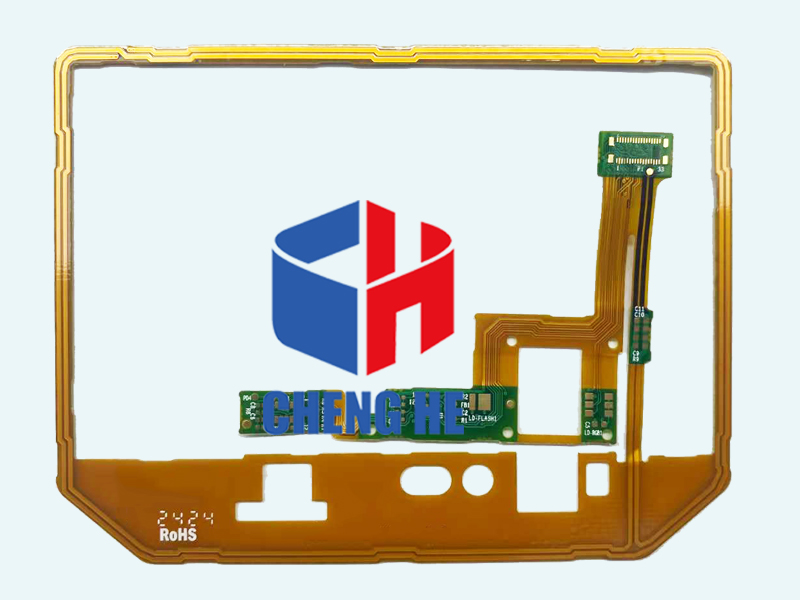

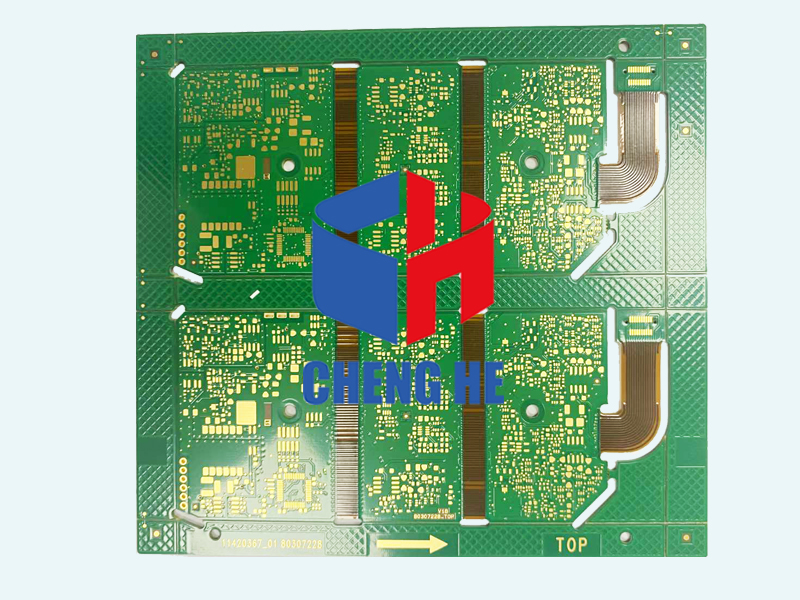

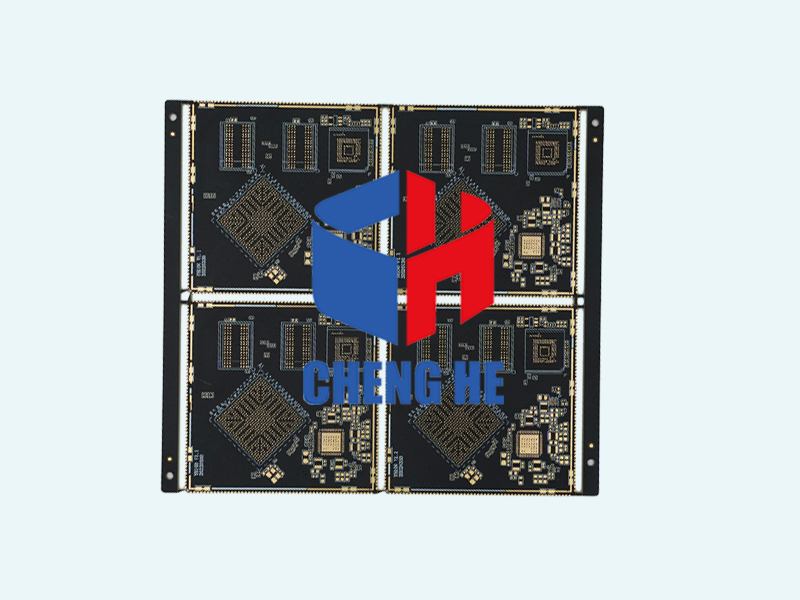

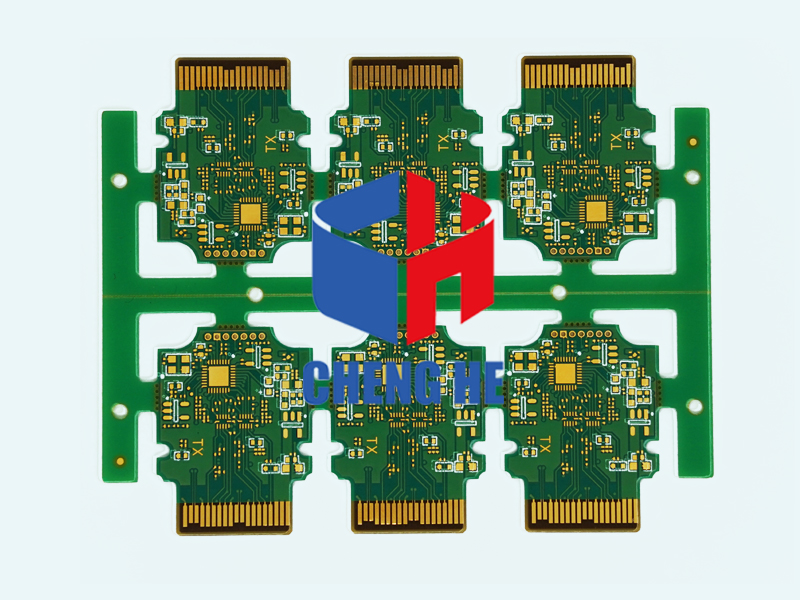

Advantages of Rigid-Flex PCB

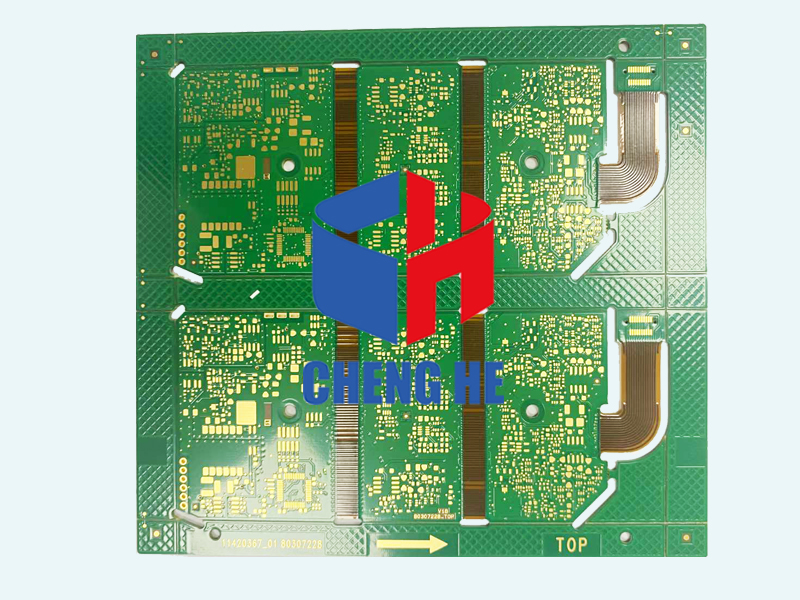

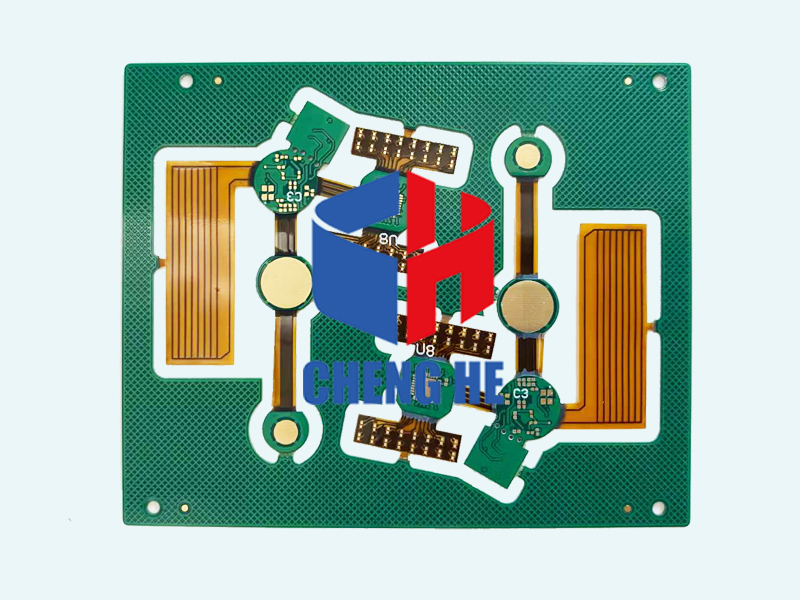

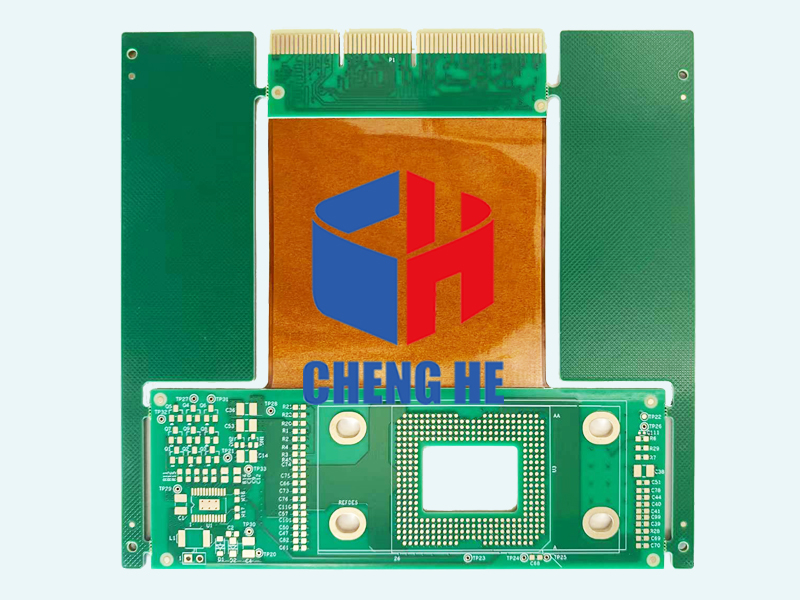

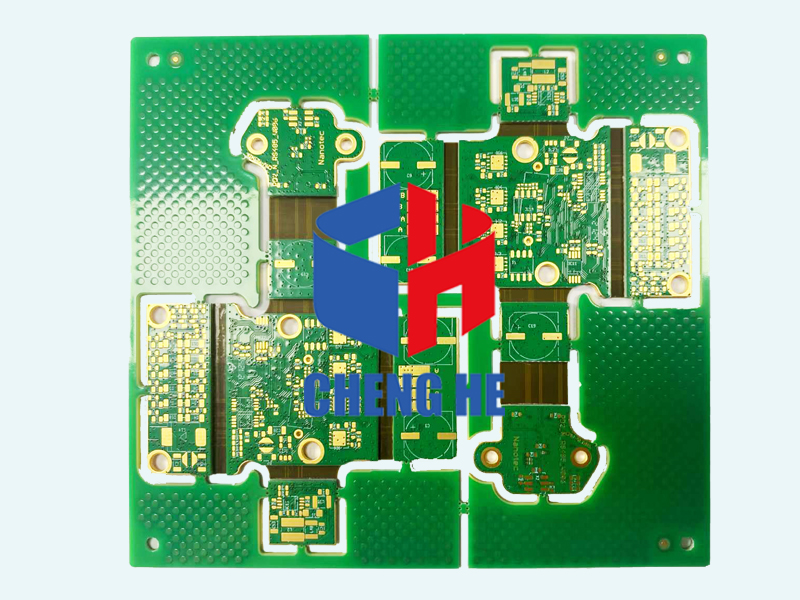

🍁Three-dimensional assembly

Enables optimized packaging, Can be bent or folded to fit intosmall device enclosures

🍁Increase system reliability

lmproves reliability by eliminating separate boards, cables and connectors.

🍁Reduce assembly error

Reduces the errors common in hand wired assemblies

🍁Reduce packaging complexity

Substantial weight & packaging size reduction is a benefit over wires and wire harnesses

🍁Better signal transfer

Minimalgeometry changes to cause impedance discontinuities

🍁Reduce assembly cost

Cost reduction in purchasing, logistics and assembling becauseof economisation of extra cables, connectors and soldering

What Are the Challenges in Designing Rigid-Flex?

Complex Design Rules: Rigid-flex PCBs often have more complex design rules compared to rigid PCBs. Designers need to understand the mechanical and electrical requirements of both rigid and flexible sections, including bend radii, layer stackup, and material constraints.

Bend Radius Considerations: One of the critical aspects of rigid-flex design is determining the appropriate bend radius for the flexible sections. Choosing a bend radius that's too small can lead to mechanical failure and signal integrity issues.

Material Selection: Selecting the right materials for both the rigid and flexible portions of the PCB is crucial. Different materials have varying thermal expansion coefficients, which can lead to reliability problems during temperature variations.

Signal Integrity and EMI: Maintaining signal integrity and controlling electromagnetic interference (EMI) in the flexible sections can be challenging. The flexibility of the substrate and the proximity of signals to the bend region can affect signal quality.

Connector Placement: Deciding where to place connectors to transition between the rigid and flexible sections is a critical design decision. Poor connector placement can lead to mechanical stress and reliability issues.

Layer Transition: Properly transitioning signal layers from the rigid to the flexible sections can be challenging. Misalignment or improper layer transitions can result in impedance mismatches and signal degradation.

Thermal Management: Managing heat dissipation in rigid-flex designs can be more challenging than in traditional rigid PCBs. The flexibility of the substrate may limit the use of traditional heat-sinking methods.

Assembly and Manufacturing: The assembly process for rigid-flex PCBs can be more complicated than for rigid boards. Designers must consider how the board will be assembled and ensure that components can be placed and soldered correctly.

Testing and Inspection: Inspecting and testing rigid-flex PCBs can be more challenging due to their complex, three-dimensional nature. Specialized testing equipment and procedures may be required.

Mechanical Reliability: Ensuring that the flexible sections can withstand repeated bending and flexing without mechanical failure is essential, especially in applications like wearables or foldable devices.

Cost: Rigid-flex PCBs can be more expensive to manufacture than traditional rigid boards due to the complexity of the design, materials used, and manufacturing processes.

Design for Manufacturability (DFM): Achieving good manufacturability in rigid-flex designs can be difficult. Designers must consider the capabilities and limitations of the manufacturing processes and work closely with fabricators to ensure a successful build.

Environmental Factors: Rigid-flex PCBs may be exposed to harsh environments in applications like automotive or aerospace. Designers must consider factors like moisture resistance, corrosion protection, and thermal cycling.

Design Verification: Rigorous testing and verification processes are essential to ensure that the final rigid-flex PCB meets all specifications and performance requirements.

whatsapp

whatsapp