What is the use of BGA on circuit boards?

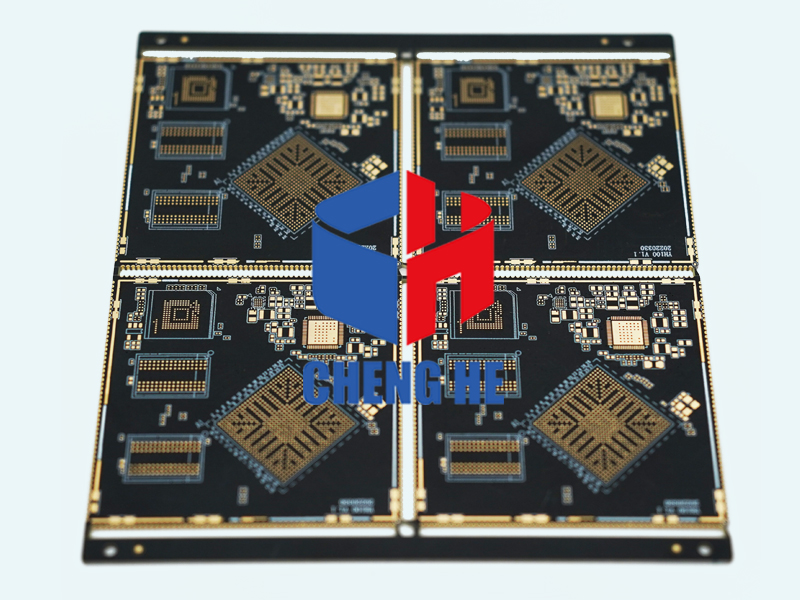

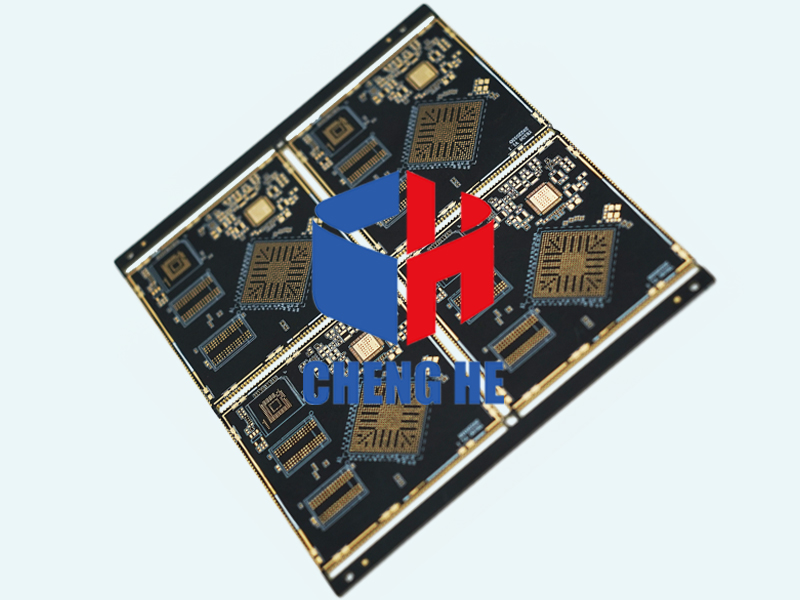

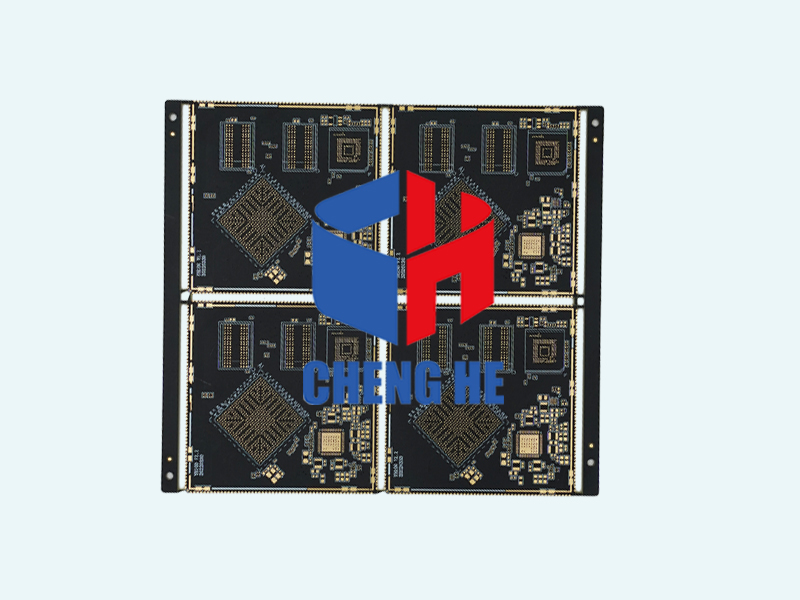

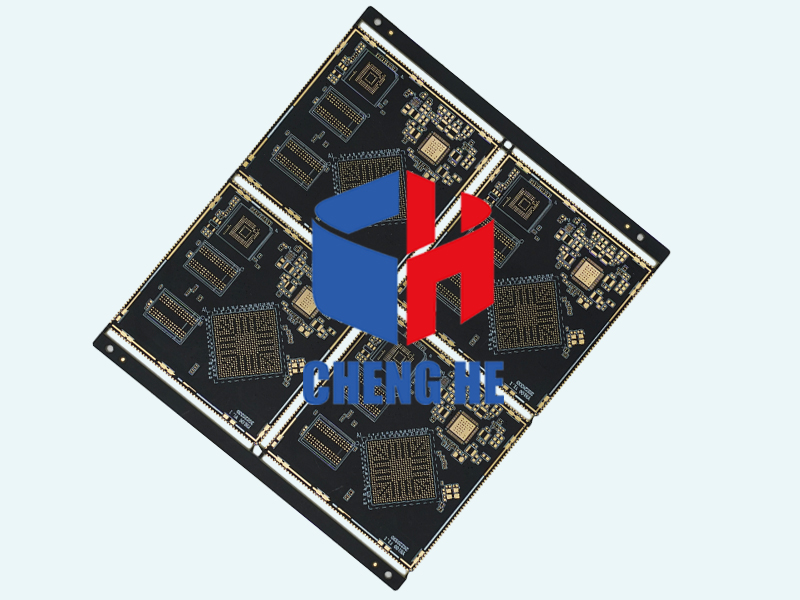

The use of BGA (Ball Grid Array Package) on circuit boards is mainly for the packaging of integrated circuits.

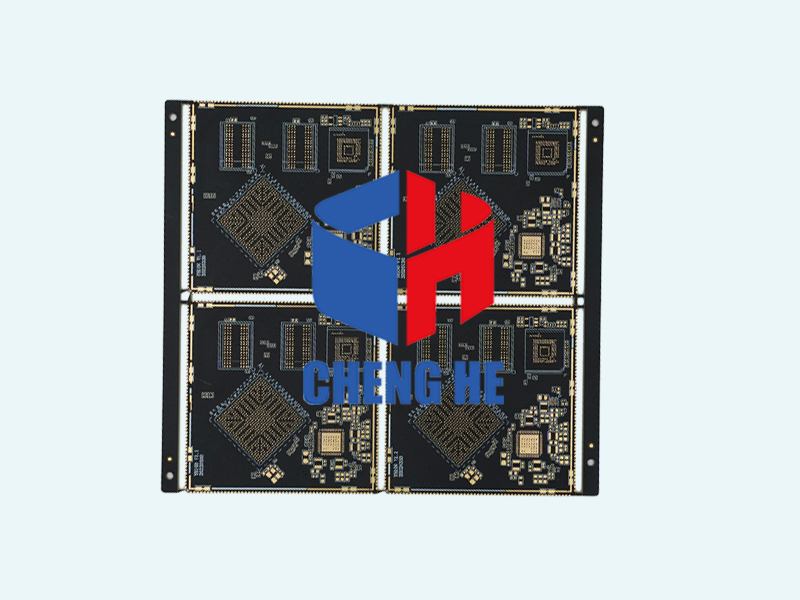

BGA packaging technology is an advanced integrated circuit packaging technology, mainly used in modern computers and mobile devices, such as memory and processors and other integrated circuits.

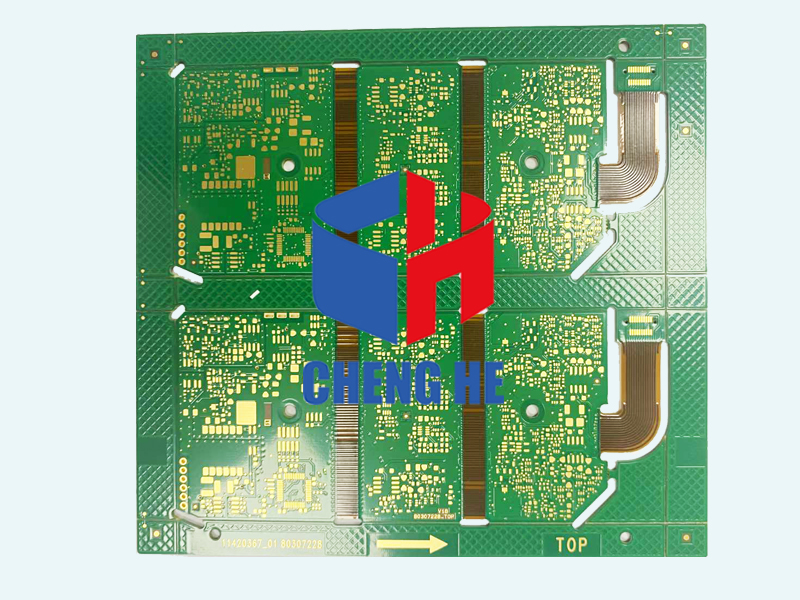

Compared with traditional packaging methods, BGA packaging has a smaller size, better heat dissipation and electrical properties, and can increase memory capacity by two to three times in the same volume. This packaging technology uses round or columnar solder joints in the form of an array distributed in the package below the I / O terminals, the advantage is that although the number of I / O pins increased, but the pin spacing has not been reduced, thus improving the assembly yield.

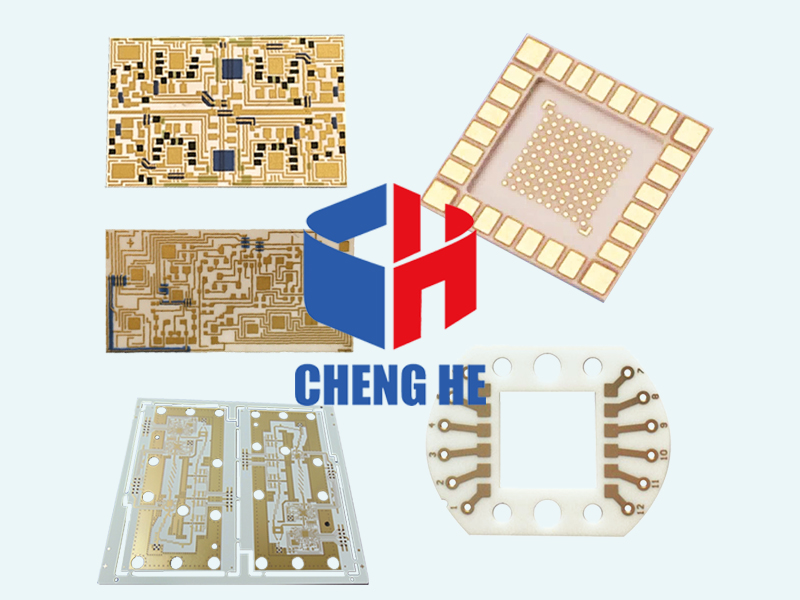

BGA package power consumption increases, but the use of controlled collapse chip method of welding can improve its electrical and thermal performance. In addition, the substrate or middle layer in the BGA package is a very important part of the package, in addition to interconnect wiring, can also be used for impedance control and for inductance/resistance/capacitance integration, requiring substrate materials with a high glass transition temperature, high dimensional stability and low moisture absorption, with better electrical performance and high reliability.

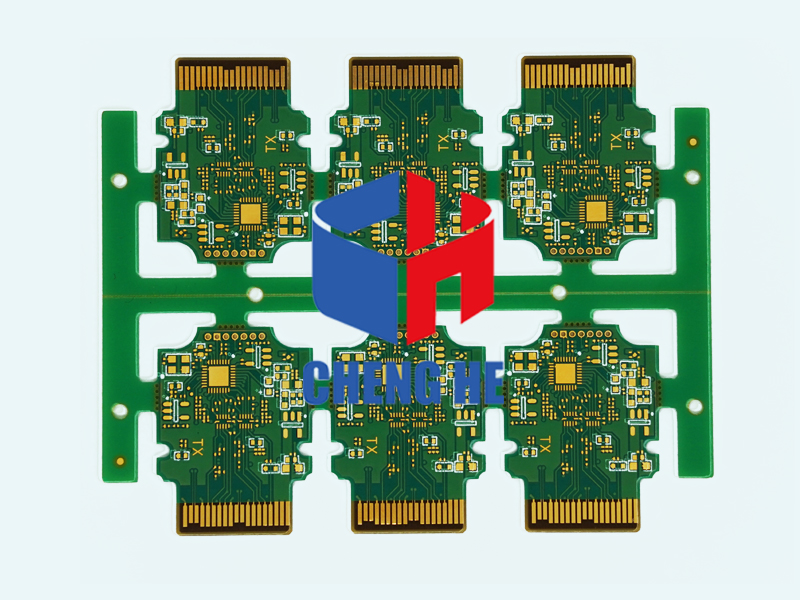

BGA packaging technology usually uses lead bonding, plasma cleaning, molding encapsulation, assembling solder balls, reflow soldering and other processes. After the BGA components are welded on the PCB board , the BGA fixing adhesive is used to strengthen and reinforce the BGA components, which can play the role of anti-fall, anti-drop, anti-vibration, anti-impact, so that the BGA components are not easy to desolder on the PCB board to improve the stability and reliability of the electronic products, and prolong the service life of the electronic products.

In summary, the application of BGA encapsulation technology on the circuit board is mainly reflected in the improvement of IC packaging density, thermal performance and electrical properties, while optimizing the encapsulation process and material selection to further enhance the reliability and service life of electronic products.

whatsapp

whatsapp